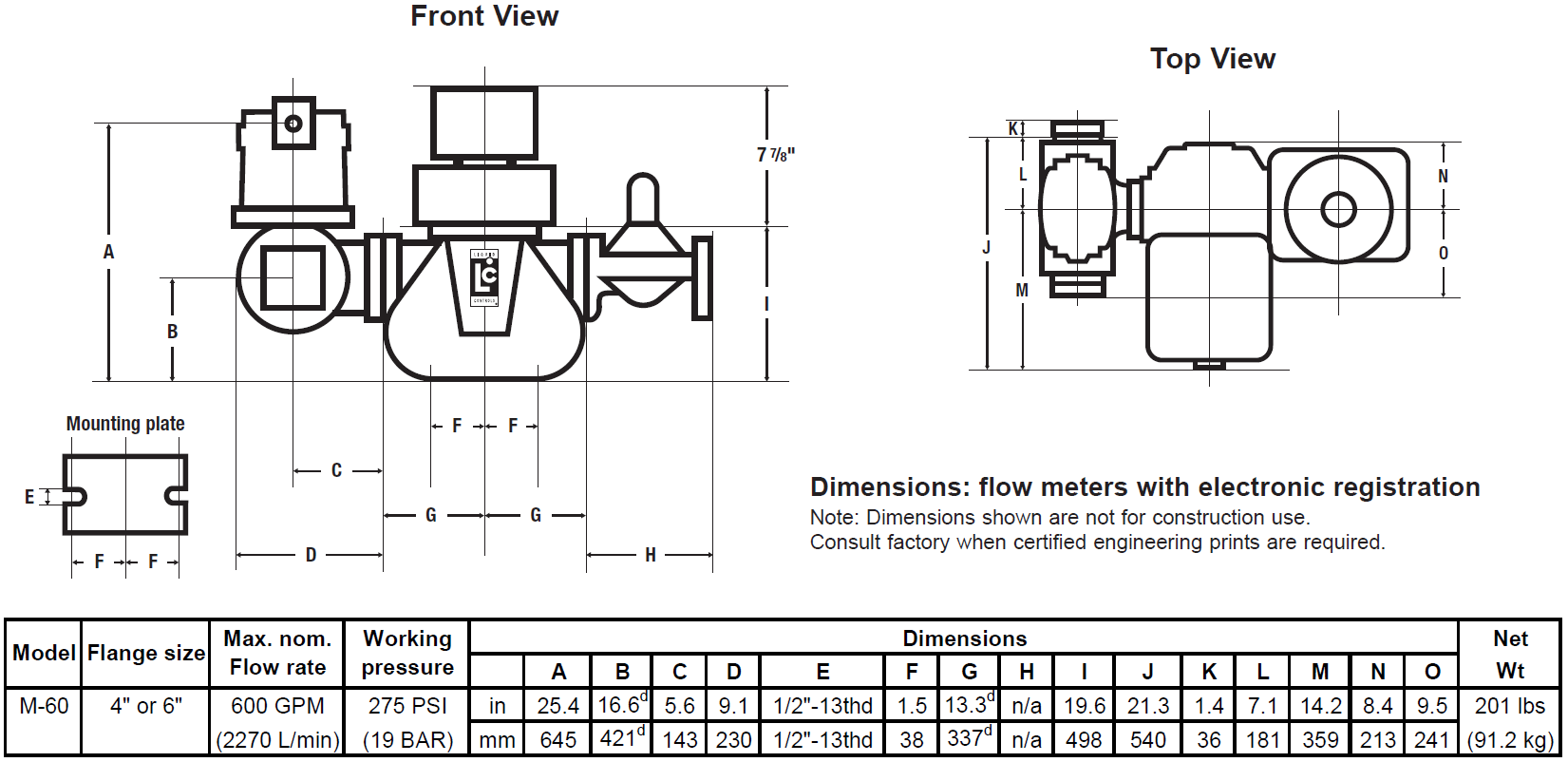

M60 — 6" LC Meter (2,800 LPM)

Rating: 2,800 LPM, 150 psi (10.3 bar, 1034 kPa)

Flange: 4″

Meter Construction: Aluminum

Seals: Buna/Viton® as noted by catalog number

Maximum Pressure: 275 psi (as listed by catalog number)

Temperature: -40° to 185° F

-

Original Products

-

Warranty Against Defects

-

Returns & Refunds Policy

-

Ships Worldwide

-

Dedicate Support

- Features

- Class 1 Meters

- Class 2 Meters

- Dimension

- Meter Flow Rates Vs. Viscosity

| Meter Classes | Description | Bearing Material |

|---|---|---|

| 1 | Refined petroleum products | Carbon |

| 2 | Aviation and jet fuel | Carbon |

|

M60A1 METER WITH REGISTRATION |

|||||||

|

CATALOG NUMBER |

FLOW |

UNIT OF MEASURE |

SEALS |

TEMP. COMP. |

SOFTWARE |

W&M APPROVAL |

|

|

LCR.iQ® REGISTRATION |

|||||||

|

M60A1-LCR.IQ-I#1 |

L-R |

LITRES |

BUNA |

N/A |

N/A |

NIST |

|

|

LCR®-II REGISTRATION |

|||||||

|

M60A1-LCR2-I#2 |

L-R |

WH GAL |

BUNA |

N/A |

SL200 ST202 |

NIST |

|

|

MECHANICAL REGISTRATION |

|||||||

|

M60A1-MECH-NP#1 |

L-R |

WH GAL |

BUNA |

N/A |

N/A |

NIST |

|

|

M60A1-MECH-NP#2 |

L-R |

DEKALITRES |

BUNA |

N/A |

N/A |

NIST |

|

|

M60A1-MECH-NP#4 |

L-R |

DEKALITRES |

BUNA |

N/A |

N/A |

OIML |

|

|

M60AT1-MECH-NP#1 |

R-L |

WH GAL |

BUNA |

YES |

N/A |

NIST |

|

M60P1

METER LESS REGISTER AND GEAR PLATE

|

CATALOG NUMBER |

FLOW |

UNIT OF MEASURE |

SEALS |

W&M APPROVAL |

|

|

LESS REGISTER AND GEAR PLATE |

|||||

|

M60P1-LRG#1 |

L-R |

DEKALITRES |

VITON® |

OIML |

|

|

M60P1-LRG#2 |

L-R |

WH GAL |

VITON® |

NIST |

|

M60S1

METER WITH POD (PULSE OUTPUT DEVICE)

|

CATALOG NUMBER |

FLOW |

UNIT OF MEASURE |

SEALS |

W&M APPROVAL |

|

|

POD (PULSE OUTPUT DEVICE) |

|||||

|

M60S1-POD#1 |

L-R |

WH GAL |

VITON® |

NIST |

|

|

M60S1-POD#2 |

L-R |

LITRES |

VITON® |

CAN |

|

|

M60S1-POD#3 |

L-R |

WH GAL |

BUNA |

NIST |

|

M60A2

METER WITH REGISTER

|

CATALOG NUMBER |

FLOW |

PRESSURE |

UNIT OF MEASURE |

PORT ORIENTATION |

TEMP COMP. |

SOFTWARE |

W&M APPROVAL |

|

|

LCR.iQ®REGISTRATION |

||||||||

|

M60A2-LCR.IQ#1 |

L-R |

275 |

WH GAL |

LOW |

N |

N/A |

NIST |

|

|

M60AT2-LCR.IQ#1 |

L-R |

275 |

LITERS |

LOW |

Y |

N/A |

OIML |

|

|

LCR®600 REGISTRATION |

||||||||

|

M60AT2-LCR600-I#1 |

L-R |

275 |

WH GAL |

LOW |

Y |

SL600 ST600 |

NIST |

|

|

MECHANICAL REGISTRATION |

||||||||

|

M60A2-MECH-NP#1 |

L-R |

275 |

WH GAL |

LOW |

N |

N/A |

NIST |

|

|

M60A2-MECH-NP#2 |

L-R |

275 |

DEKALITRES |

LOW |

N |

N/A |

OIML |

|

|

M60AT2-MECH-NP#1 |

L-R |

275 |

WH GAL |

LOW |

Y |

N/A |

NIST |

|

|

M60AT2-MECH-NP#2 |

R-L |

275 |

WH GAL |

LOW |

Y |

N/A |

NIST |

|

|

M60AT2-MECH-NP#4 |

R-L |

275 |

WH GAL |

HIGH |

Y |

N/A |

NIST |

|

|

M60AT2-MECH-WP#2* |

L-R |

275 |

WH GAL |

LOW |

Y |

N/A |

NIST |

|

|

M60AT2-MECH-WP#5** |

L-R |

275 |

WH GAL |

LOW |

Y |

N/A |

NIST |

|

|

SETUP FOR ELECTRONIC REGISTRATION |

||||||||

|

M60A2-SUFE#1*** |

R-L |

150 |

WH GAL |

HIGH |

N |

N/A |

NIST |

|

*PROVIDED WITH 10 PPR DRY REED PULSER

**PROVIDED WITH 100 PPR SOLID STATE PULSER

***VITON® ELASTOMERS

M60P2 METER LESS REGISTER AND GEAR PLATE

|

CATALOG NUMBER |

FLOW |

PRESSURE |

UNIT OF MEASURE |

PORT ORIENTATION |

TEMP COMP. |

W&M APPROVAL |

|

|

LESS REGISTER AND GEAR PLATE |

|||||||

|

M60P2-LRG#1 |

L-R |

150 |

DEKALITRES |

LOW |

N/A |

OIML |

|

|

M60P2-LRG#2 |

L-R |

150 |

WH GAL |

HIGH |

N/A |

NIST |

|

M60S2 METER WITH POD (PULSE OUTPUT DEVICE)

|

CATALOG NUMBER |

FLOW |

PRESSURE |

UNIT OF MEASURE |

PORT ORIENTATION |

TEMP COMP. |

W&M APPROVAL |

|

|

POD (PULSE OUTPUT DEVICE) |

|||||||

|

M60S2-POD#1 |

L-R |

150 |

DEKALITRES |

LOW |

N |

NIST |

|

|

M60S2-POD#2 |

L-R |

150 |

LITRES |

LOW |

N |

OIML |

|

Use the chart below to determine maximum meter flow rate relative to meter bearing material and product viscosity:

- Determine the percent of rated capacity at which the meter will be required to operate;

- Determine product viscosity at system operating temperature;

- Plot the point on the chart where the two lines intersect;

- Determine the meter bearing material from construction/application table above and locate the corresponding slope on the chart.

If the plotted point is above the bearing material slope, you are outside the allowable pressure loss for the specified meter and bearing. You should either chose a larger meter, reduce flow rate, or consider alternative bearing materials.