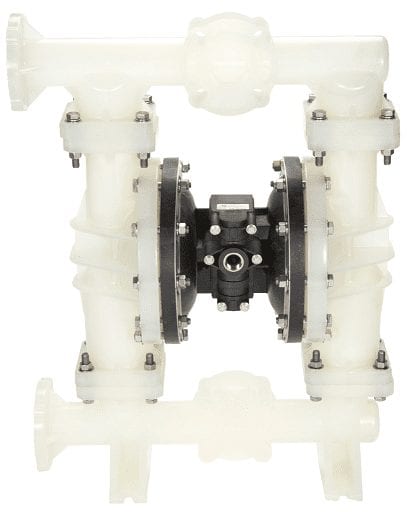

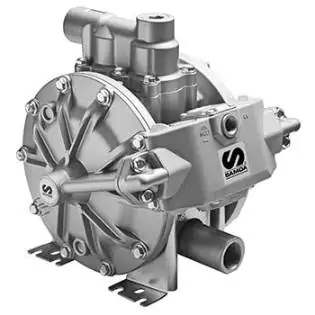

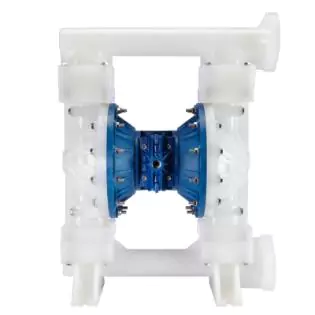

Polypropylene

A075-NPP-GGPN-S70

NPT, Geolast® Diaphragm, Geolast® Ball, Polypropylene Seat, Buna-N O-Ring, Stainless Steel Hardware

A075-BPP-GGPN-S70

BSPT, Geolast® Diaphragm, Geolast® Ball, Polypropylene Seat, Buna-N O-Ring, Stainless Steel Hardware

A075-NPP-SSPE-S70

NPT, Santoprene® Diaphragm, Santoprene® Ball, Polypropylene Seat, EPDM O-Ring, Stainless Steel Hardware

A075-BPP-SSPE-S70

BSPT, Santoprene® Diaphragm, Santoprene® Ball, Polypropylene Seat, EPDM O-Ring, Stainless Steel Hardware

A075-NPP-TTPT-S70

NPT, PTFE Diaphragm, PTFE Ball, Polypropylene Seat, PTFE O-Ring, Stainless Steel Hardware

A075-BPP-TTPT-S70

BSPT, PTFE Diaphragm, PTFE Ball, Polypropylene Seat, PTFE O-Ring, Stainless Steel Hardware

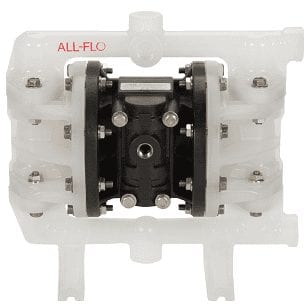

PVDF

A075-NPK-SSKE-S70

NPT, Santoprene® Diaphragm, Santoprene® Ball, PVDF Seat, EPDM O-Ring, Stainless Steel Hardware

A075-BPK-SSKE-S70

BSPT, Santoprene® Diaphragm, Santoprene® Ball, PVDF Seat, EPDM O-Ring, Stainless Steel Hardware

A075-NPK-TTKT-S70

NPT, PTFE Diaphragm, PTFE Ball, PVDF Seat, PTFE O-Ring, Stainless Steel Hardware

A075-BPK-TTKT-S70

BSPT, PTFE Diaphragm, PTFE Ball, PVDF Seat, PTFE O-Ring, Stainless Steel Hardware

Cconductive Nylon

A075-NPY-TT3T-S70

NPT, PTFE Diaphragm, PTFE Ball, Stainless Steel Seat, PTFE O-Ring, Stainless Steel Hardware

A075-BPY-TTYT-S70

BSPT, PTFE Diaphragm, PTFE Ball, Nylon Seat, PTFE O-Ring, Stainless Steel Hardware

.webp)

.webp)

.webp)